High quality in the production cycle

A quality product is a product that fully meets the needs of those who use it. Quality management is reflected in both strategy and company operations. Therefore, quality cannot be considered only as an element of the marketing mix or a purely technical or technological factor, but a lever that involves all the company’s activities, resources and functions.

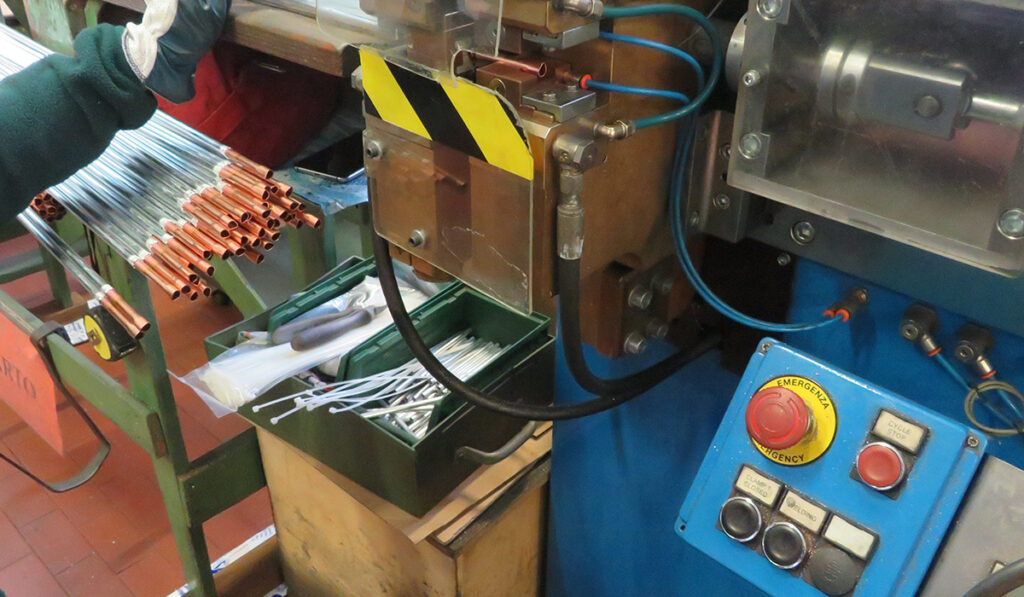

Preparation

The choice of raw materials of the highest quality is followed by the first phases of verification and preparation of the material

Processing

The first assembly processes are managed with precision and in manual mode by expert personnel.

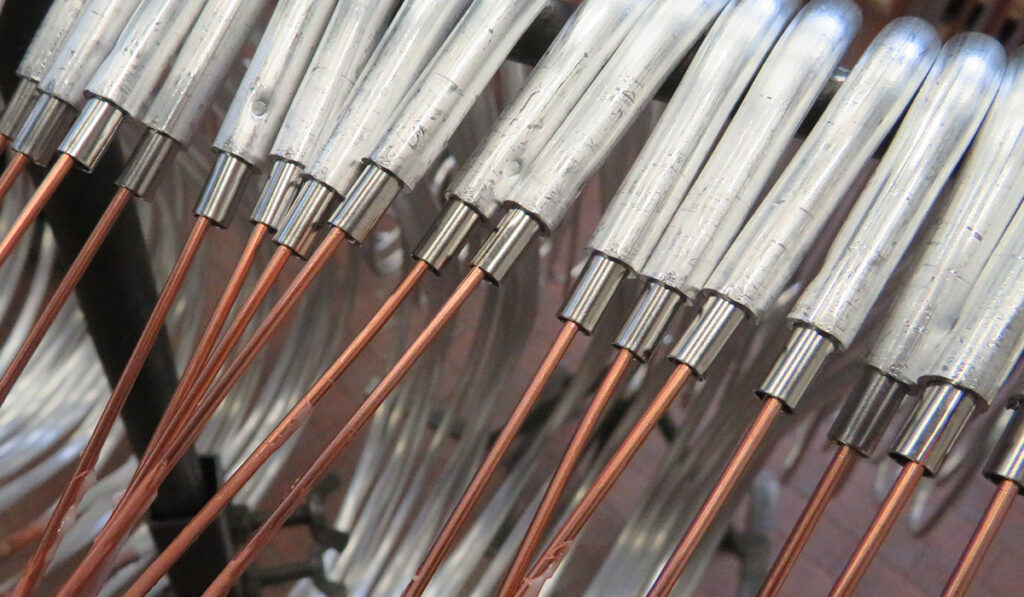

Welding

Among the fundamental processes that require experience and precision is the welding of the parts

Welding

After careful preparation, the highly manual welding process takes place.

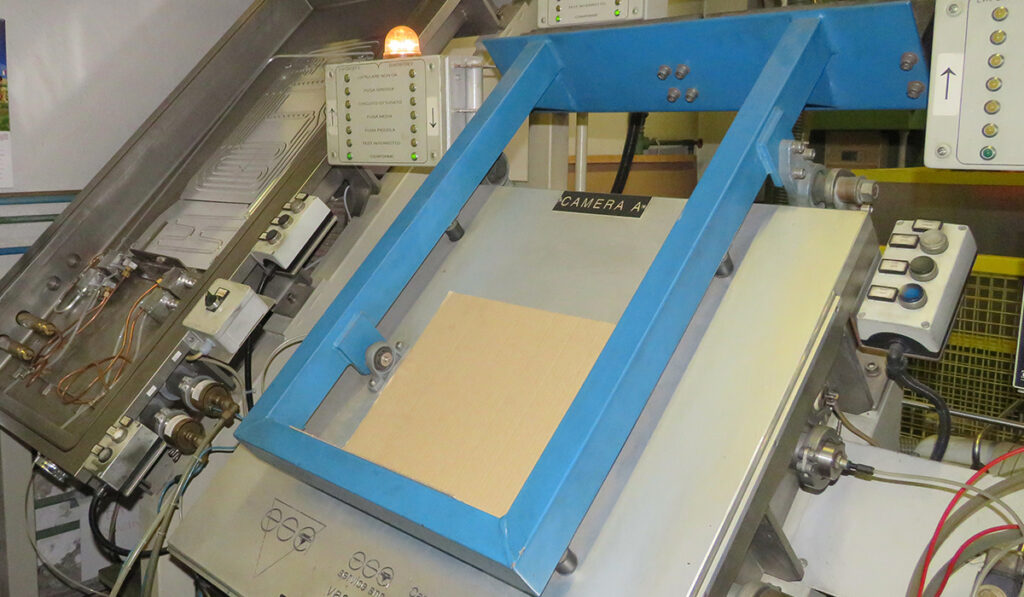

Tightness tests

To respect high product quality levels, each piece is tested and certified individually.

Final Testing

In the final stages of production, after the leak tests, every single piece is inspected.

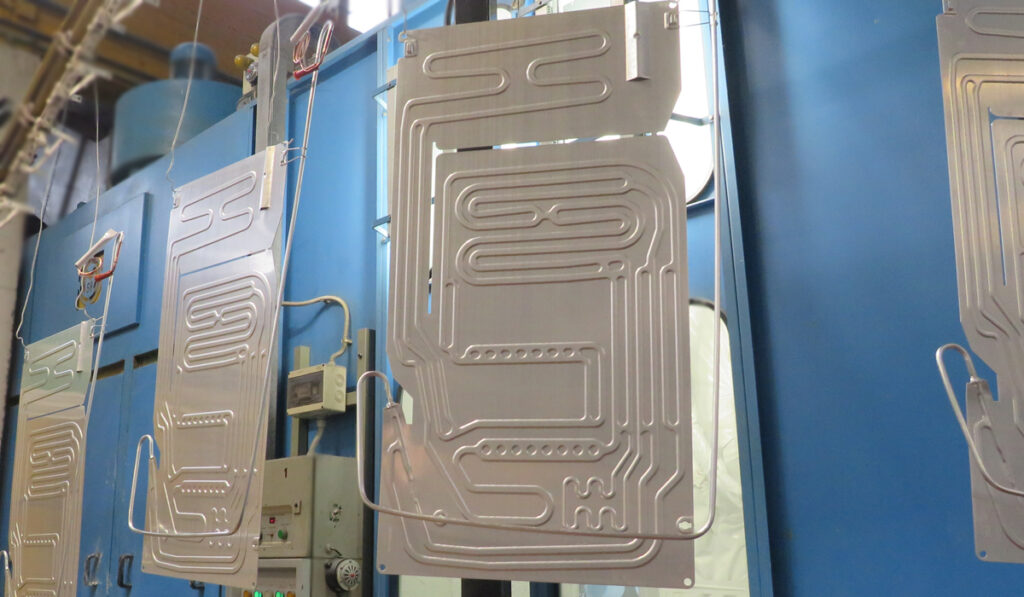

Painting

The painting takes place with automated processes, robots and high-quality paints with high resistance.

Storage

To guarantee rapid deliveries, a large storage warehouse guarantees the satisfaction of this need.

Logistic

A rapid and efficient logistics allows Ols to meet the customer’s important production times.